Hydrogen Fuel Cells

New forms of heat pumps and hydrogen heating are urgently needed to meet the 2050 zero carbon targets. Recent reports state that the country will not achieve its emission targets while continuing to use natural gas namely a fossil fuel for heating. A third of the countries greenhouse emissions emanate from central heating,

Fuel cells are devices that convert chemical reactions into low-voltage DC electricity and heat. A fuel cell generates electricity through an electrochemical reaction, not combustion. In a fuel cell, hydrogen and oxygen are combined to generate electricity, heat, and water. Fuel cells are used today in a range of applications, from providing power to homes and businesses such as hospitals and fuel for transport including cars, buses, trucks, forklifts, trains. A great deal of investment and research is being carried out at present into the full potential of hydrogen fuel cells. It could become the fuel of the future. A multitude of techniques for creating hydrogen are being developed.

Fuel cell systems are a very clean, efficient, reliable, and quiet source of power. Fuel cells do not need to be periodically recharged like batteries, but instead continue to produce electricity as long as a fuel source is provided.

A fuel cell is composed of an anode, cathode, and an electrolyte membrane. A typical fuel cell works by passing hydrogen through the anode of a fuel cell and oxygen through the cathode. At the anode site, a catalyst splits the hydrogen molecules into electrons and protons. The protons pass through the porous electrolyte membrane, while the electrons are forced through a circuit, generating an electric current and excess heat. At the cathode, the protons, electrons, and oxygen combine to produce water molecules. As there are no moving parts, fuel cells operate silently and with extremely high reliability.

Fuel cells that use pure hydrogen fuel are completely carbon-free, with their only byproducts being electricity, heat, and water. Some types of fuel cell systems are capable of using other fuels like natural gas, biogas, methanol, and others. Because fuel cells generate electricity through chemistry rather than combustion, they can achieve much higher efficiencies than traditional energy production methods such as steam turbines and internal combustion engines. To push the efficiency even higher, a fuel cell can be coupled with a combined heat and power system that uses the cell’s waste heat for heating or cooling applications.

Fuel cells are also scalable. This means that individual fuel cells can be joined with one another to form stacks. In turn, these stacks can be combined into larger systems. Fuel cell systems vary greatly in size and power, from combustion engine replacements for electric vehicles to large-scale, multi-megawatt installations providing electricity directly to the utility grid. Most important they are eco-friendly no carbon emissions

I wonder what impact the continued introduction of hydrogen fuel cells will have on the plumbing profession.

Modularity/ Off-Site Construction Revisited.

I would like to return to the topic of modular/off-site construction as it could impact significantly on the profession as will the introduction of artificial intelligence and robots both could create a revolution in the way plumbers operate. Interest is growing in this development as the advantages are being highlighted with a number of large companies who are beginning to invest in the process.

It involves some or all of the fabrication or assembly of components being carried out within the controlled environment of the factory or workshop rather than on- site.

Even though the associated costs are much the same modular manufacturing has a number of advantages over traditional methods of construction some are given below:

* Time factors namely it takes to build traditionally is approximately six months whilst to construct a modular house is three to four months.

* Removing site processes to the controlled environment of the factory or workshop will improve the rate of production and product quality. Improved process will lead to reduced levels of waste and subsequent costs. The use of CNC machines will improve efficiency. Also with improved control of materials flow, raw materials can be recycled rather than be skipped which often happens on site.

* With fewer activities being undertaken on site less time should be required for on-site activities where conditions are less predictable and controllable.

* Modular construction is not effected by the weather e.g. in winter and wind affecting crane activities.

* The units can be easily transported to remote locations again reducing the overall cost. However, traditional construction also requires materials to be transported from their point of manufacture to the site, sometimes involving frequent, though often short distances.

* Quality, standards, inspection and control issues will be improved. Building components assembled on-site is often prone to workmanship defects, which cost client and the industry considerable sums each year. Much better cost control will be achieved. The control of components assembled in a factory environment can benefit from more rigorous quality assurance checking. Therefore off-sit construction has the potential to deliver a product that has fewer opportunities to acquire defects.

Modular construction will present significant challenges to all the trades including the plumbing profession whether in the domestic and commercial enterprises. Significant changes will also occur at the onsite installation stage. It will also require fundamental changes in the training people preparing to enter the trades. Further Education Colleges (FECs) and other training organisations will need to make major reforms to the way they operate. In addition specific training of site operatives may be required to implement some systems correctly. As said above many see these developments as a revolution.

Colleges and training providers need to be helped and supported by the manufacturing company’s and professional bodies that represent the trades. In addition the various trades must collaborate more. Equally important college management needs to recognise these challenges and in turn support the lecturers and trainers by providing adequate resources. The training of lecturers and trainers will also need to be significantly reformed as will the training of students wishing to enter the industry. One significant change will be how the various trades work together in the new working environments including closer collaboration between the professional bodies.

I would be interested to hear from lecturers and plumbers on how they see the possible impact on their current practices as modular manufacture increases in scale.

https://en.m.wikipedia.org/wiki/Ernst_Neufert

https://en.m.wikipedia.org/wiki/Plattenbau

Artificial Intelligence and Plumbing

Robots already perform many practical activities in manufacturing industries but the key question is to what level will be ultimately achieved and the impact of workers on plumbing.

Let’s now reflect on the implications for the plumbing profession. Clearly the consequences are different for on- site installation, problem solving as well as the manufacturing stage of the components and is critically dependent of the plumber’s employment status. Many plumbers work with large companies whilst many are self-employed and this will present different issues and challenges to the workers. These elements coupled with the development of modular/off-site construction offers a number of challenges when introducing AI and the use of robots into the profession.

I am not plumber but have a great respect for the profession indeed all the trades having worked in technical education. I have also always valued the work of the professional institutes that represent the trades. The professional institutes are very important in representing their respective trades and that is why it is essential that practitioners are members particularly at this critical time.

I have the honour of chairing the Education and Training Group for the CIPHE. So I write as an enthusiastic outsider. The institute and ETG have been discussing this issue and will continue to do so.

The impact of AI and the introduction of robots will be different for on-site installation and at the manufacturing phase of the components. Clearly the manufacture of the components will be done by robots as in other industries. However the real challenges arise with onsite installation and problem solving.

It is the issues associated with on-site installation and problem solving that I think raises fundamental questions about the extensive use of robots. Very often plumbers come across unexpected problems and it is their previous experience and knowledge that solves these often unique problems. I think robots will not be able to achieve this however well programmed they are. The human touch for me is fundamental. Whilst on the human touch one of the appealing aspects of plumbing for domestic and commercial enterprises is the relationship that develops between the plumber and the customer I think that will be seriously diluted with the introduction of robots. This will be true for all the trades.

Another issue is associated with the actual working environment for the plumber which is very often very limited and cramped so it could present problems when using robots. The limitations of space could create major limitations in regard to the size of the robots. Also the age of the plumbing system could present problems depending on its scale and complexity of the system. Again the human touch will prove invaluable and again I think be beyond the robot capabilities.

I would be interested in what practicing plumbers think about this fascinating topic and also their views on the development of modular construction. Their working styles could be changed fundamentally so it would be great to hear their views.

The Importance of Workplace Mathematics

Questions continue to be raised about the teaching and learning of mathematics in schools and colleges and the levels of participation in the subject post-16. Questions continue to arise about its purpose and centrality in the schools national curriculum and the introduction of functional mathematics in vocational awards. In addition, concerns are being raised about the quality and quantity of students entering further and higher education to study courses that require mathematics such as plumbing.

We live in a technological society based on mathematics and science, so it is concerning that schools, colleges and universities continue to turn out students in large numbers who not only lack adequate mathematical and numeracy skills.

There needs to be national debates on this topic that will establish a consensus about these problems with the subjects and how to resolve them. Equally importantly is the urgent need to recognise and identify the problems associated with these subjects in the workplace. Work-based mathematics and numeracy are often overlooked and neglected. Meaningful research on mathematics and numeracy in the work place has been minimal and as a result there is a dearth of evidence and even then scant attention paid to what the real issues are.

It is also essential to develop more precise definitions of the various elements involved. In any research there is a requirement that a precise lexicology is developed and adhered to. These requirements are important given the different mathematical and numerical skills and competences that exist in different work place situation Key questions need to be answered including:

- What mathematical and numerical skills are important in each identified work situation and how best are these identified?

- What attitudes towards numeracy and mathematics need to be developed and encouraged by employers, employees, parents and teachers?

- How best can these subjects be taught and learnt in traditional classroom situations and how important is the context in which teaching and learning takes place?

- How does the context of numeracy and mathematics in the workplace become formalised in order to bring about an identification and understanding of the kind of skills that are needed in a given setting?

In the limited research on numeracy in the workplace issues about the lack a feeling for number has been identified as a problem. It would seem that the school curriculum particularly at primary level has paid little attention to this extremely important element and it remains to be seen if the numeracy strategy will bring about a sustained and lasting improvement. The inability to manipulate and understand the fundamental operations associated with number creates later problems irrespective of the ultimate aspiration of the learners. For example, the inability to estimate and transpose numbers and equations makes for fundamental difficulties later.

Too often in the past, reforms to the mathematics curriculum diluted the above essential building blocks for numeracy skills. The relevance and fitness of purpose of the school/college mathematics content needs to match the future needs and aspirations of the learners.

This is important, as the young adults leaving these institutions will enter a wide variety of work situations and occupations that will in turn require varying degrees of numerical and mathematical skills and competences. Careful analysis is needed to identify and then introduce the appropriate content at the right time into the curriculum.

Clearly there are fundamental elements that all learners require to learn but with the necessary differentiations that reflect their career intentions. It must be accepted that very few will study mathematics to any depth whilst the vast majority will require a basic foundation and grounding in numerical skills and mathematical techniques in order to cope with the demands of chosen occupations. The curriculum needs to be configured to recognise these demands and at the same time excite and stimulate the learners whatever their needs.

One real challenge for the curriculum reformers is the fact that the whole curriculum is restrictive because of including other key curriculum subjects. The expectation that numerical skills and mathematical techniques taught in schools and colleges should be capable of satisfying the total needs of the learners whatever their career intention is absurd. The content must be seen as relevant and be significantly informed by employers. Employers and their professional institutes must be involved in assisting the identification of what is required in their particular work place. Sadly to date this essential element has been lacking.

The farce surrounding the introduction of functional mathematics again highlighted that there is still a long way to go before the problems with the teaching and learning of work based mathematics and numeracy are resolved.

Vocational Qualifications

A rewarding aspect of managing my website (1) is the feedback in emails I receive from readers. Whether positive or negative this is always welcome and valuable. Sadly a recurring theme highlights the continuing negative perception of vocational and commercial qualifications.

One theme often expressed is readers’ experience of negative attitudes to their vocational qualifications when they apply for jobs or further study or training. These qualified people studied for various technical and commercial awards over the past few decades, managed and offered by a number of agencies which did not involve the so called academic awards e.g., ‘O’ levels, GCSEs . ‘A’ levels and university degrees.

Their experience has been that these qualifications are often not recognised at all when they apply for jobs or further studies. Over the past few decades a number of initiatives were established that attempted to introduce a long overdue set of nationally accepted vocational and commercial awards. These included the numerous schemes agreed by the Man Power Services Commission (MSC) and which were offered in Further Education Colleges and private providers. Examples of these initiatives included the Youth Training Scheme, (YTS). Youth Opportunities Programme (YOP) (2).

Another major initiative was the Technical Education Initiative (TVEI) with programmes offering a wide range of awards in FE colleges, schools and private training providers.

In addition a number of separate initiatives including some managed by the Department for Education/Education Department (ED) and the major awarding bodies e.g. CGLI and RSA e.g. Certificate of Pre-Vocational Education (CPVE), General National Vocational Qualifications (GNVQs), Graduate Apprenticeship Diploma (GADs) and Vocational Diplomas (VDs).

Thousands of students studied under these initiatives and gained certificates when successful. The initiatives were never really supported by central government, educationalists and sadly many teachers – those who preferred to extoll the virtues and value of academic awards. The initiatives were short lived and never fully evaluated ever though many of us felt they were bringing about a set of valuable alternatives to the academic wards and creating parity of esteem between these awards.

However the people who contacted me were very concerned about the issues that they had experienced in relation to these awards especially when applying for jobs and further educational studies. The most difficult matters related to obtaining replacement certificates if for instance originals had been lost, mislaid or damaged in the intervening years and they needed the evidence of their achievements.

Individuals found that interviewers knew nothing about the awards or initiatives and insisted on seeing the certificates and diplomas. When people then contacted the colleges, local authorities and the Education Department to get replacement certificates they were told that no records or archives existed.

After receipt of these emails I followed up this issue with the Education Department, Local Authorities and individual colleges mentioned in readers emails describing their experiences without success. They all said that no records are kept or if an archive existed it has been dismantled often stating that they did not have the physical space to store such material!?

In addition to people contacting me I have even been contacted by overseas nations asking about these qualifications following applications by people to enter their countries. The countries have told me that they contacted the Education Department etc. and were told that no details or records were available. I then attempted to describe the awards and there value and received very positive feedback.

It is a classic example of the negative view of vocational qualifications in this country and also the casual disregard of the obligation to store such information about people’s formally recognised national achievements. The academic awards are underpinned by comprehensive recording systems but not so for the vocational awards.

It will be interesting to see if the proposed ‘t’ awards suffer the same fate.

First published in the ETM Journal for the Chartered Institute of Plumbing and Engineering in Spring 2019.

References:

(1) www.technicaleducation matters.org

(2) More detail on these initiatives and awards are on the website

What Worth is the Annual Budget

It’s always interesting to reflect on discussions leading up to the annual budget. The same themes are restated with monotonous regularity with promises to reduce the national debt, improve productivity and boost funding for key policy areas such as the national health, education, redeveloping the manufacturing base and creating a world class economy. Sadly as in previous years little happens after the announcements: it’s a classic example of empty political rhetoric and tokenism.

This year’s’ budget is no different; before the announcements a great deal of media coverage raised the crucial and central problems of productivity in the manufacturing and services industries. Facts and figures abounded in the press and mass media as in previous years. German and France are respectively 36% and 30% more productive than this country. The growth rate in the country continues to be the lowest in Europe and one of the lowest in the developed nations. Politicians stressed the urgent need to address this fact and other employment issues e.g. the situation with wages growth.

A recent report has indicated that the current stagnation in wage increases will persist 2025 and then only to the level in 2008! Productivity has been a problem for many years and shows no sign of improving and it will get worse following Brexit. Practically all aspects of the economy are flat lining. One major theme in this year’s budget was the urgent need to build 300,000+ houses but how can that happen with the massive skill shortage of key tradespeople e.g. plumbers, joiners, brick layers etc.! Also it takes at least one generation to increase numbers of teachers and change attitudes of young people to enrol into technical subjects and enter technical professions. These facts reflect that successive governments focus on single issues to gain public favour when they should adopt a holistic approach recognising all the interconnected elements.

The central problem is the national debt is massive – the country is bankrupt with the true level not being openly declared. When you include all the elements of the debt including personal, pensions and corporate the figure is truly astronomical and will never be cleared whatever the politicians and some economists say or through austerity policies. The exit from the EU will further worsen the situation it will be a true dogs Brexit in all senses!

The problems as previously stated in earlier articles are long standing and fundamental. Solutions to tackle once and for all these issues require radical, long term policies supported by all political parties. Short termism is one of the key problems with this country in political and financial organisations.

Countries that have adopted long term policies are far more successful with international trade and possess effective technical education and training systems and as a result do not possess skill shortages and gaps.

Here, investment in key areas such as technical education and training must be operated for the long term and without government interference. Even when Further Education (FE) was adequately funded it was only on a short term basis and often linked to limited initiatives and schemes e.g. the Manpower Services Commission, programmes like TVEI, GNVQs et.al. The majority of these initiatives were very politically driven and sadly technical education was seen as being second class, including in terms of their contribution to economic success, when compared with schools and universities.

Important elements that need to be addressed: (It’s all been said before).

(1) Radical and long term policies must be introduced and supported by all political parties.

(2) Politicians need to recognise all the problems confronting this country once and for all and be more open and honest with the general public.

(3) Politicians also need to recognise that it takes a generation to rectify the problems. This is especially true for education and training

(4) The central role of technical education and training and the FE sector must be fully recognised in solving the present problems with skills and productivity in the work place.

(5) Employers, professional bodies and trade unions must be involved more in shaping technical education and training policy.

(6) Work law and existing practices must be reviewed and reformed in order to recognise the rapidly changing nature of work e.g. automation, robotics Artificial intelligence et al.

(7) Funding to tackle the very poor productivity in employment areas especially in manufacturing industries.

(8) Adequate funding for practical subjects in schools must be provided and the current cuts stopped and the importance of practical vocational subjects fully recognised.

(9) Partnerships between all the education and training sectors must be increased.

(10) Careers advice and information must be improved providing positive message about technical and practical subjects and their associated careers.

(11) The multitude of negative consequences of Brexit, if it happens, must be recognised and contingency plans made otherwise the situation will get even worse

This year’s budget again failed to consider many of the above issues and it when it addressed issues like the proposed industrial strategy and productivity did so in a superficial manner and short time fashion. The budget must form a crucial element of any plan to reform the fundamental problems that confront this country.

Further Thoughts on Economics

This viewpoint reflects on what economics and the implementation of the current economic models means in the light of the massive transformations are occurring. The increasing recognition that the current economic models and capitalism have failed and must be fundamentally reviewed and reformed. Many people in the past have argued that economics is an art and not a science. It is clearly related to the social sciences. As globalism evolved with the resultant national economies becoming more complex and internationally connected the current definitions and interpretations are now seen as being too simplistic. Many factors impact on economies such as volatility in the oil price and stock exchanges and the sudden and unexpected changes in the political complexion in countries. The current economic theories and doctrines are increasingly seen to be inadequate in dealing with these multidimensional, variable and often contradictory factors. Recently many commentators have been highly critical of economics voicing its failures over the past few decades and calling for fundamental reviews and reforms to the current practices.

It will be interesting to discuss and compare economics with the evolution of science and scientific methodology. For example two distinct historical phases can be identified with physics namely Newtonian Physics (Classical Mechanics) and Relativity/Quantum Physics (Quantum Mechanics). Newtonian Physics dealt with the observable world and the universe that was then known i.e. the macro world. It depicted with a high degree of accuracy the appearance of eclipses, explained the action of tide and the behaviour of forces particularly that of gravity. Over the centuries after its formulation further confirmation of its validity gave rise to a view that is was the ultimate explanation and represented the absolute truth. Many scientists became arrogant and believed it could explain all the phenomena in the then known world and universe. However once research began of atomic physics and investigations into the micro world this view was quickly dispelled by Albert Einstein and the founders of quantum physics including Werner Heisenberg and Erwin Schrodinger and Max Planck. Quantum mechanics replaced classical mechanics for microscopic phenomena but was still able to accomodate classical mechanics and the macro world.

However the major difference between the two approaches was that instead of the belief of absolute prediction and certainty quantum mechanics gave results that were based on probability and uncertainty. Examples of this were the Heisenberg uncertain principle and the two slit paradox. The former was that there is a fundamental limit of an atomic particle and its momentum can be simultaneously known. Also there is a fundamental limit to the energy of an atomic particular when it is measured for a finite time. The product of the two uncertainties must be greater than Planck’s constant dived by 2pi. The reason for this uncertainty is that the method of measuring says the position of an atomic particle perturbs that position resulting in uncertainty of its position in a sense it creates a cloud of uncertainty.

The two slit experiment showed the fascinating and perplexing fact that light could be both a wave and particle (photon) often referred to as wave particle duality. Light behaves as a wave when being propagated and a particle when interacting with matter. For example interference and diffraction shows light as a wave and the photoelectric effect as a particle. So the quantum revolution created a totally different theory for physics. In many ways modern physics has become more like philosophy.

So can economics and its currently practised theories learn anything from this scientific revolution? Economists and the models they practice have massively failed to predict the financial crisis of 2008 and continue to provide no meaningful view or prognosis of the current dire state of the world’s economy. Instead they continue to promulgate traditional views and theories whether these are based on Classical, Keynesian, Supply and Demand, Capitalism, Market Socialism or Laissez Faire approaches. These theories include introducing; Quantative Easing (QE), low or negative interest rates and austerity which have made the situation worse. Many of these approaches are based on debt accumulation which will ultimately lead to even bigger problems for individual countries and the world. The message seems to be manage the situation in a misguided way but do not solve it!

So could economics develop new and more reliable models in the future by fundamentally reforming current practices? If so could economics learn anything from the scientific revolution described above that would hopefully lead to a better recognition and management of the factors that create economic crisis? I think a starting point is the recognition of the complexities and consequences of the impact of numerous connected. It would be interesting if a new set of theories could be developed writing algorithms that introduce elements of a Heisenberg Uncertainty Principle and adopt a more realistic view of the limitations of these theories.

However the majority of economists adhere to the current and flawed models of managing world and national finances. They resist any attempts to fundamentally review and reform the current approaches. Let’s hope some will realise that the current models and practices are urgently in need of reform.

James Prescott Joule (1818-189)

(British physicist, mathematician and brewer born in Salford Lancashire was a brilliant experimenter and scientist who studied the nature of heat and laid the foundations to thermodynamics and kinetic theory through a number of pioneering discoveries and initiatives).

James Prescott Joule was born on New Bailey Street, Salford near Manchester on 24th December 1818 son of Benjamin and Alice Prescott and was one of five children. His father was a wealthy brewer a business which he succeeded to later in his life. He was mostly home-schooled by his aunt and later studied arithmetic and geometry under John Dalton a famous chemist at the Manchester Literary and Philosophical Society. He later studied under the famous scientist and lecturer John Davies.

James Prescott Joule was born on New Bailey Street, Salford near Manchester on 24th December 1818 son of Benjamin and Alice Prescott and was one of five children. His father was a wealthy brewer a business which he succeeded to later in his life. He was mostly home-schooled by his aunt and later studied arithmetic and geometry under John Dalton a famous chemist at the Manchester Literary and Philosophical Society. He later studied under the famous scientist and lecturer John Davies.

Slightly deformed, with symptoms of spinal problem, Joule started working in his father’s office at the age of 15 where he acquired an interest in science and came to to appreciate the relationships between the temperatures and pressures of gases, between pumping and heating, simply by observing the brewery in operation. Interest to note this was similar to Priestley who studied the properties of carbon dioxide in a brewery. Joule was driven by a powerful love of experimental investigations and was an outstanding experimenter.

Joule studied twice a week under John Dalton then president of the Manchester Philosophical Society from 1817 to 1844. Dalton was largely responsible in imbuing Joule love of experimentation. When he was 19 years of age Joule converted one of his father’s rooms into a laboratory and constructed an electro-magnetic engine and published his first scientific paper. He submitted his first findings for publication to William Sturgeon’s ‘Annals of Electricity’.

In 1840 he replaced the brewery’s steam engines with electric motor and achieved greater efficiencies. In 1841 he carried out an experiment to establish the relationship between electrical resistance and heat in a conductor this became known later as Joule’s first law.

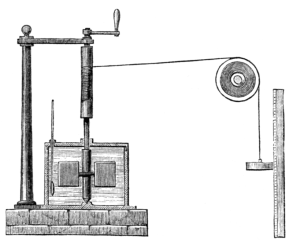

In 1843 Joule announced his discovery what became the first law of thermodynamics *(see below) which related the relationship between energy and work. In 1844 he measured the ratio of work needed to compress a gas to the heat of 4.27 joules/calorie. In 1845 Joule reported an experiment using a paddle wheel (see the two diagrams below) to understand the conservation of energy. He proposed that in the experiment mechanical energy was converted into heat emery and this later became known as the ‘Law of Conservation of Energy’.

By 1849 he showed the indestructibility of energy – the conservation of energy, the mechanical equivalent of heat and the existence of absolute zero. He provided the foundation for mathematicians to develop the theory of heat and the importance of efficiency of heat engines on their working temperatures.

By 1849 he showed the indestructibility of energy – the conservation of energy, the mechanical equivalent of heat and the existence of absolute zero. He provided the foundation for mathematicians to develop the theory of heat and the importance of efficiency of heat engines on their working temperatures.

He did not need the prestige of being a university professor to promote his discoveries to the world of science. For example in 1847 at the age of 28 he presented a lecture explaining his discovery of the laws of the conservation of energy at St. Ann’s Church, Manchester.

He read papers at the British Association at Cork (Ireland) in 1843, at Cambridge in 1845 and Oxford in 1847. Before he reached the age of 30 he was elected to honorary membership of the Royal Academy of Science at Turin and the Royal Society.

In 1854 he sold the brewery and moved to Oak Fields, Whalley Range. South Manchester and continued to work for long hours and paid little attention to his health. In 1861 he moved again to Thorncliffe, Old Trafford. Throughout his research he attracted criticisms from neighbours about the noise of his experimental engines.

He had met William Thomas also known as Lord Kelvin in 1847 at one of his presentations at the British  Association in Oxford and later worked closely with him making many important discoveries including the Joule-Thomson effect – namely measuring the temperature changes when forcing a gas or liquid through a valve kept insulated so that no heat is exchanged with the environment and the concept of absolute zero. They also further improved the efficiency of steam engines especially for marine use. The two men laid the foundations of kinetic theory including the velocities of molecules through air. They worked together for over ten years. He also worked closely with Lyon Playfair who was a strong advocate of technical education (See biography on this website).

Association in Oxford and later worked closely with him making many important discoveries including the Joule-Thomson effect – namely measuring the temperature changes when forcing a gas or liquid through a valve kept insulated so that no heat is exchanged with the environment and the concept of absolute zero. They also further improved the efficiency of steam engines especially for marine use. The two men laid the foundations of kinetic theory including the velocities of molecules through air. They worked together for over ten years. He also worked closely with Lyon Playfair who was a strong advocate of technical education (See biography on this website).

He often suggested that his theories linking heat and mechanical work would show that the water at the bottom of water falls would be higher than at the top and he with others to visit the Niagara to verify this finding.

In 1878 he received a civil list pension of £200 per annum from the British government in recognition of his services to science.

Joule achieved ground breaking discoveries over a period of forty years and is now recognised for this by the adoption of the Joule the S.I. physical unit of work/energy.

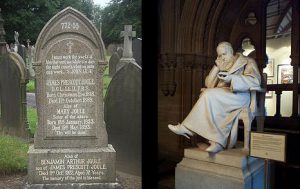

Joule died on 11th October 1889 and buried in Sale at the age of 70 years. The gravestone is inscribed with his 1878 measurement of the mechanical equivalent of heat namely 772.55 a figure which is very close to todays’ value again showing his brilliance as a researcher (Se diagram below). A statue of him by Alfred Gilbert is placed at the entrance of Manchester Town Hall opposite to John Dalton (See diagram below). A pub located in Sale ‘The J P Joule is named after him and the family brewery now exists in Market Drayton.

Honours: Fellow of the Royal Society (FRS) 1850. RS Medal 1852, Albert Medal (RS) 1880, Copley Medal 1870 and a number of honorary degrees.

President of Manchester Lit and Phil Society 1860. President of the British Association for the Advancement of Science 1872.

Key:

- When heat is converted to work, the process is never totally efficient, e.g. when steam drives a piston, most of the heat energy in the steam is converted to mechanical energy but some is wasted heating up the sides of the cylinder. The first law of thermodynamics states that the energy used in doing work will be equal to the amount of work done – that energy cannot be created or destroyed.

References:

J P Joule. ‘On Matter, living force, and heat’. Lecture given in 1847, reprinted in S.G. Brush. ‘Kinetic Theory’ Volume 1. ‘The Nature of Gases and of Heat’. New York: Pergamon Press. 1965.

Joule. J.P. ‘The Scientific Papers of James Prescent Joule’. London. Dawson’s. 1965.

Bottomley, J.T. ‘James Prescott Joule’. Nature. 26. Pages 617-20. 1882.

Cardwell, D. S. L. ‘James Joule: A Biography’. MUP. ISBN 0719034795. 1991.

Fox, R. ‘James Prescott Joule 1818-1889’. In J. North. ‘Mid-19th Century Scientists’. Elsevier. ISBN 0-7190-3479-5. 1969.

Steffens. H. J. ‘James Prescott Joule and the Concept of Heat’. Watson. ISBN 0-88202-170-2. 1979.

James Brindley (1716-1772)

(James Brindley a pioneer in canal building and a brilliant civil engineering designed a number of important canals and made a number of inventions. He played a significant role in developing the way canals were built during the Industrial Revolution transforming the British landscape and helping to unlock a new aspect of the Industrial Revolution).

James Brindley was born at Tunstead, near Buxton, Derbyshire. He moved with his family to Leek to farm as a labourer. In his spare time he carved model windmills with a small pocket knife which were then geared to turn a paddle wheel which highlighted his innate practical ability. In 1733 he was apprenticed for seven years to a wheelwright Abraham Bennett who lived in Sutton near Macclesfield. Bennett was not a good master spending most of his time drinking and neglecting his duties to the apprentice Brindley. As a result he learnt very little but gradually started teaching himself having to carry out emergency repairs whilst Bennett was absent. In the autumn of 1735 a small silk mill at Macclesfield and owned by Michael Daintry was damaged and Bennett allowed Brindley carry out the repairs. He impressed the mill superintendent James Milner who predicted that Brindley would become a gifted craftsman. With Milner’s support and encouragement after he finished the Daintry Mill other mill owners approached him and this work expanded both in scale and range. People often asked him how he had become a good worker and often said ‘it came natural-like’ and he was called ‘the Schemer’. Bennett at first thought Brindley was a bungler in-spite of not supporting him but soon realised Brindley was a very skilled and became Bennett’s right hand man after the work for Daintry’s mill and as a result this saved Bennett’s business which ten gained its professional reputation. He remained with Bennett after his apprenticeship ended, running the business until his employer’s death.

James Brindley was born at Tunstead, near Buxton, Derbyshire. He moved with his family to Leek to farm as a labourer. In his spare time he carved model windmills with a small pocket knife which were then geared to turn a paddle wheel which highlighted his innate practical ability. In 1733 he was apprenticed for seven years to a wheelwright Abraham Bennett who lived in Sutton near Macclesfield. Bennett was not a good master spending most of his time drinking and neglecting his duties to the apprentice Brindley. As a result he learnt very little but gradually started teaching himself having to carry out emergency repairs whilst Bennett was absent. In the autumn of 1735 a small silk mill at Macclesfield and owned by Michael Daintry was damaged and Bennett allowed Brindley carry out the repairs. He impressed the mill superintendent James Milner who predicted that Brindley would become a gifted craftsman. With Milner’s support and encouragement after he finished the Daintry Mill other mill owners approached him and this work expanded both in scale and range. People often asked him how he had become a good worker and often said ‘it came natural-like’ and he was called ‘the Schemer’. Bennett at first thought Brindley was a bungler in-spite of not supporting him but soon realised Brindley was a very skilled and became Bennett’s right hand man after the work for Daintry’s mill and as a result this saved Bennett’s business which ten gained its professional reputation. He remained with Bennett after his apprenticeship ended, running the business until his employer’s death.

He was approached in 1750 by the brothers Wedgewood John and Josiah who were operating a small pottery business near Stoke but were struggling in getting sufficient powdered flint an essential material for the pottery. Brindley then built mills which could produce flint powder at Burlsem located near Leek. The following ten years he worked on a number of water and wind mills and became interested in steam engines and subsequent installed several atmospheric engines. Josiah Wedgewood invited Brindley to join the Lunar Society (see website)

As his reputation grew he was approached by John Heathcote owner of the Clifton collieries near Manchester to drain his mines which were flooding and that the traditional methods at that time were not effective. This was his most ambitious project when he created a drainage scheme that took water from the River Irwell through an underground tunnel over 731 metres long that ran under the river to drive an overshot wheel, which then pumped out the mine. This achievement highlighted his brilliance at engineering skills, knowledge of hydraulic problems and innovation

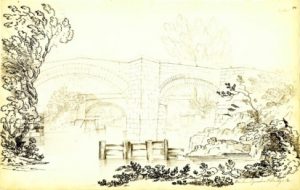

He also built five tunnels and a number of aqueducts at Harecastle, Hermitage, Barnton, Saltenford, Preston-on-the Hill and Barton. Harefield tunnel was not completely finished until 1777 five years after Brindley’s death and was at the time the longest man-made tunnel on the world being approximately 2,750 metres. The quality and scope of his work catapulted him into a national figure. Eventually he became a rich person and in his will left £7,000 a considerable sum in those days in-spite of money owed to him by the Duke of Bridgewater estate and other sponsors. Barton is shown below.

He also built five tunnels and a number of aqueducts at Harecastle, Hermitage, Barnton, Saltenford, Preston-on-the Hill and Barton. Harefield tunnel was not completely finished until 1777 five years after Brindley’s death and was at the time the longest man-made tunnel on the world being approximately 2,750 metres. The quality and scope of his work catapulted him into a national figure. Eventually he became a rich person and in his will left £7,000 a considerable sum in those days in-spite of money owed to him by the Duke of Bridgewater estate and other sponsors. Barton is shown below.

Brindley suffered from diabetes throughout his life and this coupled with his incredible workloads resulted in his final illness whilst surveying the Trent and Mersey canal at Froghall and subsequent death at the age of 56. He is buried at St James, Newchapel Staffordshire.

Below are some achievements of James Brindley:

1716 Born at Tunstead, Derbyshire.

1726 Brindley family moved to Leek.

1733 Apprenticed to Bennett.

1737 Completes machinery of paper –mill for Bennett who realises what an excellent apprentice he has.

1742 He starts business as a millwright in Leek.

1750 Opens workshop at Burslem and in 1752 builds Leek Mill and starts Clifton Hydraulic Power Scheme.

1752 Constructs Leek Mill and Clifton Power Scheme.

1756 Builds a steam engine at Little Fenton and in 1758 patents a steam engine.

1758 Designed windmill to grind flint for Joseph Wedgewood. Patents design for a steam engine boiler.

1759 Partnership with Duke of Bridgewater begins.

1761 Barton Aqueduct opens to traffic.

1762 Surveys for the Chester Canal and Branch Canal to Stockport carried out.

1763 Provides advice on the Lower Avon Navigation improvements.

1764 Supervises construction of Bridgewater Canal.

1765 Appointed Engineer to the Calder and Hebble Navigation.

1766 Starts work on the Grand Trunk Canal.

1767 Surveys for Bradford, Rochdale and Stockton and Darlington Canals carried out.

1768 and 1769 Surveys for the Leeds and Liverpool, Leeds and Selby and Oxford canals carried out.

1770 Draws up plans for the Thames navigation improvements.

1771 The construction of the Chesterfield Canal starts

1772 Survey for the Lancaster Canal. Died on 27th September.

References:

Bode, H. ‘James Brindley. An illustrated life of James Brindley 1716-1772.’ Shire Publications Ltd. ISBN 0 85263 485 4. Lifelines series 14. 1992.

Boucher, C. T. G. ‘James Brindley Engineer, 1716-1772.’ Goose and Son.

Evans, K. M. ‘James Brindley, Canal Engineer – a New Perspective.’ ASIN B00LUVLMU0. Churnet Valley Books (Bath Street, Leek). 1998.

Halward, L. ‘Famous British Engineers.’ The Scientific Book Club.

Smiles, S. ‘James Brindley and the Early Engineers.’1864. Reprinted by Hanse. ISBN 9783744662192.

The Brindley Mill, a working water-driven mill restored as a tribute to him and containing the James Brindley Museum is located close to the centre of Leek in Staffordshire on the A552 between Macclesfield and Leek.

Brindleyplace in Birmingham is named after James Brindley and statues of him exist in the Coventry Basin and Etruia workshops across the Caldon Canal at Stoke-on-Trent.

Recent Comments